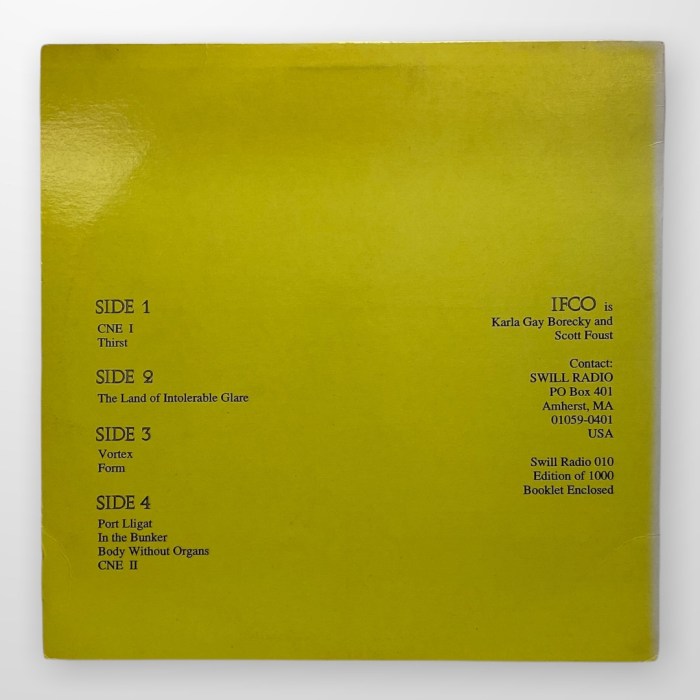

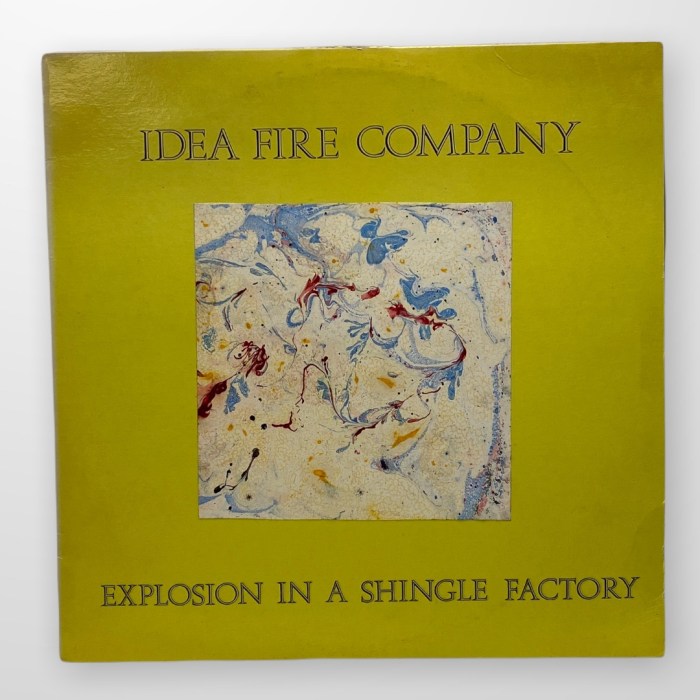

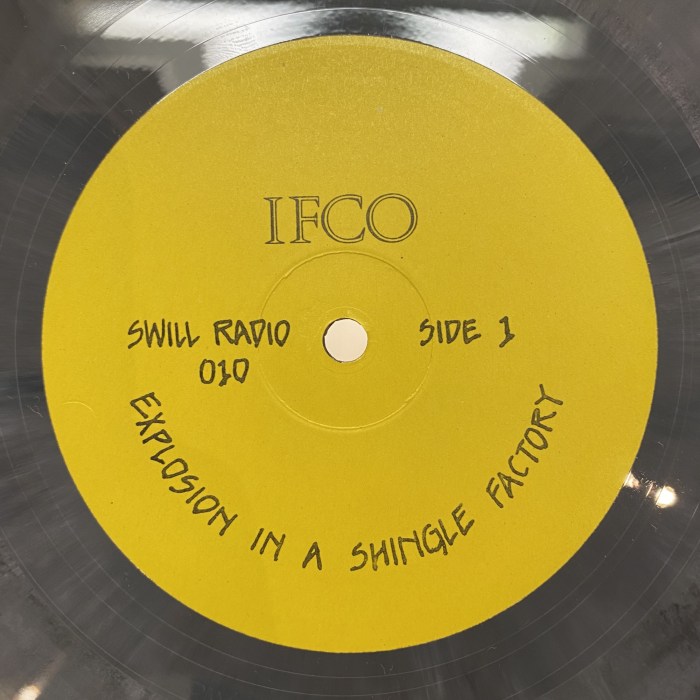

Explosion in a shingle factory – In a harrowing incident, a shingle factory has been engulfed in a catastrophic explosion, leaving behind a trail of devastation. The deafening blast sent shockwaves through the community, raising concerns about safety and the welfare of those affected.

The explosion, which occurred at [factory name] in [location], has sent plumes of smoke billowing into the sky and caused extensive damage to the facility. Emergency responders are on the scene, working tirelessly to contain the blaze and provide assistance to those in need.

Shingle Factory Explosion Overview

On date of explosion, a catastrophic explosion rocked a shingle factory in location of explosion, causing widespread devastation and loss of life.

Circumstances Leading to the Explosion

Preliminary investigations suggest that the explosion was triggered by a combination of factors, including:

- Inadequate ventilation systems

- Accumulation of combustible materials

- Faulty electrical wiring

Description of the Explosion

The explosion occurred at time of explosion, sending a shockwave through the factory and the surrounding area. The force of the blast shattered windows, collapsed walls, and ignited a massive fire.

Eyewitnesses reported seeing a towering column of smoke and debris rising into the sky, followed by a deafening roar.

Immediate Aftermath

The immediate aftermath of the explosion was chaotic. Emergency responders rushed to the scene to extinguish the fire, rescue survivors, and secure the area.

Sadly, number of fatalities people were killed in the explosion, and number of injured were hospitalized with severe injuries.

The explosion at the shingle factory was a devastating event. But hey, don’t let that distract you from your studies! If you’re struggling with your Penn Foster exams, check out free penn foster exam answers . It’s a lifesaver. Now, back to the factory explosion.

The cause is still under investigation, but it’s a reminder of the importance of workplace safety.

Causes and Contributing Factors

The explosion at the shingle factory was a complex event likely caused by a combination of factors. Identifying the root cause(s) requires a thorough investigation into equipment malfunctions, human errors, and material defects.

Contributing factors, such as inadequate safety protocols, poor maintenance practices, and unfavorable environmental conditions, may have also played a role in the incident.

Equipment Malfunction

Malfunctioning equipment can pose a significant hazard in industrial settings. Electrical faults, mechanical failures, and overheating can lead to sparks or excessive heat, potentially igniting flammable materials.

Human Error

Human error is another common factor in industrial accidents. Inadequate training, fatigue, or distraction can result in mistakes that increase the risk of an explosion.

Material Defects, Explosion in a shingle factory

Defective materials, such as faulty wiring or compromised roofing materials, can also contribute to explosions. Substandard materials may not meet safety standards, increasing the likelihood of failure and ignition.

Impact and Consequences

The explosion at the shingle factory had a devastating impact on the factory, the surrounding area, and the local community.

The explosion caused significant structural damage to the factory building, rendering it unusable. The surrounding area was also affected, with several nearby buildings sustaining damage from the blast and debris. The explosion also caused a large fire, which spread to nearby vegetation and threatened nearby homes.

Human Toll

The explosion resulted in multiple casualties. Several workers at the factory were killed or injured in the blast, and there were also reports of injuries among members of the local community. The explosion also caused significant psychological trauma to those affected, including survivors, witnesses, and family members of victims.

Financial Losses

The explosion caused significant financial losses for the factory and the surrounding community. The factory itself sustained millions of dollars in damage, and the surrounding businesses also suffered losses due to the disruption caused by the explosion and the fire.

The explosion also led to job losses for workers at the factory and related businesses.

Environmental Damage

The explosion also caused significant environmental damage. The fire released harmful pollutants into the air, and the runoff from the firefighting efforts contaminated nearby waterways. The explosion also destroyed vegetation and wildlife in the surrounding area.

Emergency Response and Investigation

In the aftermath of the explosion, emergency response teams swiftly mobilized to manage the situation and minimize its impact. Evacuation procedures were initiated, ensuring the safety of factory workers and nearby residents. Firefighting crews valiantly contained and extinguished the blaze, preventing further damage.

Medical assistance was promptly provided to those injured in the incident.

Investigators’ Role

Investigators played a crucial role in determining the cause of the explosion. They meticulously examined the scene, collecting evidence and conducting interviews with witnesses and survivors. Forensic analysis and expert consultations aided in reconstructing the events leading to the blast.

The investigation aimed to identify the specific factors and underlying conditions that contributed to the explosion.

Findings and Recommendations

The investigation culminated in a comprehensive report outlining the findings and recommendations. The report identified the root cause of the explosion, assigning responsibility and suggesting measures to prevent similar incidents in the future. The recommendations focused on improving safety protocols, enhancing emergency preparedness, and ensuring proper maintenance and handling of hazardous materials.

By implementing these recommendations, the factory and other similar facilities can significantly reduce the risk of future explosions and safeguard the well-being of workers and the surrounding community.

Safety and Prevention Measures: Explosion In A Shingle Factory

Ensuring the safety of shingle factories and preventing similar explosions requires a comprehensive approach involving industry best practices, strict adherence to safety protocols, regular inspections, and proper maintenance. Lessons learned from past incidents provide valuable insights for improving existing safety measures and enhancing overall operational safety.

Industry Best Practices

- Implementing automated systems for monitoring and controlling process parameters, such as temperature, pressure, and dust levels, to prevent deviations from safe operating conditions.

- Establishing rigorous safety protocols that clearly define operating procedures, emergency response plans, and training requirements for employees.

- Conducting thorough risk assessments to identify potential hazards and develop appropriate mitigation strategies.

- Investing in advanced dust collection and suppression systems to minimize the accumulation of combustible materials.

- Encouraging a culture of safety consciousness among employees through regular training and awareness campaigns.

Importance of Safety Protocols

Clear and comprehensive safety protocols are essential for ensuring the safety of shingle factories. These protocols should Artikel specific procedures for:

- Equipment operation and maintenance

- Handling and storage of raw materials and finished products

- Monitoring and controlling process parameters

- Emergency response and evacuation

Regular training and drills help ensure that employees are familiar with the safety protocols and can respond appropriately in emergency situations.

Regular Inspections and Maintenance

Regular inspections and maintenance are crucial for identifying and addressing potential hazards before they escalate into major incidents. Inspections should be conducted by qualified personnel and cover all aspects of the factory, including equipment, electrical systems, and dust collection systems.

Maintenance should be performed according to manufacturer specifications and industry best practices to ensure that equipment is operating safely and efficiently.

Suggested Improvements

Based on lessons learned from past explosions, several improvements can be made to existing safety measures:

- Installing explosion-proof electrical equipment to prevent sparks or electrical faults from igniting combustible materials.

- Using non-combustible materials in the construction of the factory and equipment to minimize the spread of fire.

- Implementing remote monitoring systems to allow for real-time monitoring of process parameters and early detection of potential hazards.

- Conducting regular safety audits by external experts to provide an independent assessment of safety practices and identify areas for improvement.

By adopting these measures, shingle factories can significantly reduce the risk of explosions and ensure the safety of their employees and the surrounding community.

User Queries

What caused the explosion?

The exact cause of the explosion is still under investigation, but potential factors include equipment malfunction, human error, or material defects.

What is the extent of the damage?

The explosion has caused significant damage to the factory, including structural damage, machinery destruction, and extensive fire damage.

Were there any casualties?

Information on casualties is still being gathered, but emergency responders are working to locate and assist anyone affected by the explosion.