An izod impact test was performed on – An Izod impact test is a pivotal technique in materials science, meticulously crafted to evaluate the impact strength of materials, providing crucial insights into their resilience under sudden force. This detailed analysis delves into the intricacies of the Izod impact test, unraveling its significance and practical applications.

The Izod impact test stands as a testament to scientific ingenuity, meticulously designed to measure the energy absorbed by a material as it fractures under impact. This valuable information serves as a cornerstone for material selection and design, ensuring optimal performance in real-world applications.

Test Overview

The Izod impact test is a standardized method for determining the impact strength of materials. It is used to assess the ability of a material to resist fracture under a sudden load.

The test is performed using a pendulum-like device that strikes a notched specimen of the material. The energy absorbed by the specimen during the impact is measured and used to calculate the impact strength.

Equipment

The following equipment is required to perform an Izod impact test:

- Izod impact tester

- Notched specimen of the material being tested

- Hammer

- Anvil

Procedure

The following steps are involved in performing an Izod impact test:

- The specimen is notched using a sharp blade.

- The specimen is clamped in the anvil of the impact tester.

- The hammer is raised to a specified height.

- The hammer is released, striking the specimen.

- The energy absorbed by the specimen during the impact is measured.

Specimen Preparation

The preparation of test specimens for the Izod impact test is crucial to ensure accurate and reliable results. The selection of appropriate materials, specimen dimensions, and notching techniques plays a significant role in obtaining meaningful data.

Specimen Selection and Dimensions

The material used for the specimens should be representative of the material being evaluated. The thickness of the specimen is typically chosen to be 10 mm, while the width can vary depending on the material and the specific test method used.

The length of the specimen is generally 64 mm.

Notching

Notching the specimen introduces a controlled stress concentration, which initiates crack propagation during the impact event. The notch is typically cut into the center of the specimen, perpendicular to the direction of impact. The depth and angle of the notch are standardized to ensure consistency in test results.

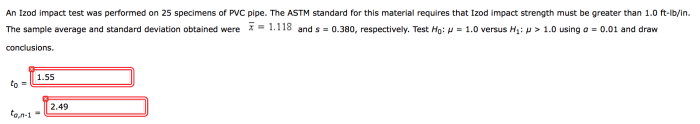

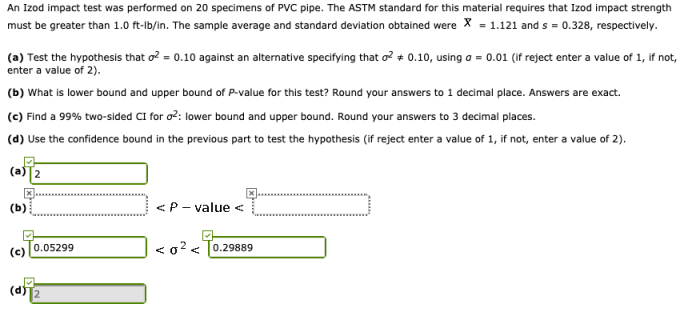

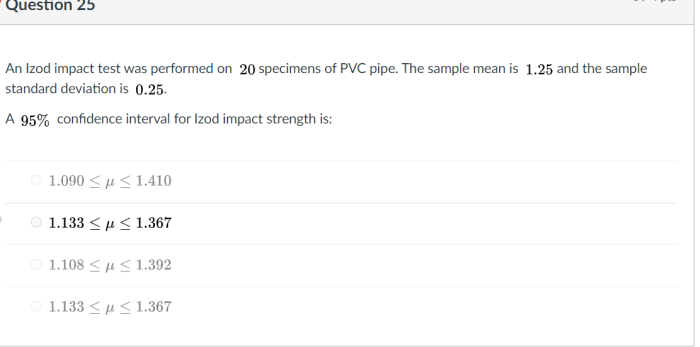

Data Analysis

The impact energy is calculated by measuring the area under the load-deflection curve obtained during the test. The impact strength value is a measure of the material’s ability to resist fracture under impact loading.

The impact strength value is significant because it can be used to compare the toughness of different materials and to predict the performance of a material in an impact loading application.

Examples of Impact Strength Data Use in Engineering Applications

- Automotive industry: To design car bumpers and other safety components that can withstand impact forces.

- Aerospace industry: To design aircraft components that can withstand bird strikes and other impact events.

- Construction industry: To design buildings and bridges that can withstand earthquakes and other impact loads.

Factors Affecting Results: An Izod Impact Test Was Performed On

The results of an Izod impact test can be affected by several factors, including temperature, specimen thickness, and notch geometry. It is important to control these factors to ensure accurate testing.

Temperature, An izod impact test was performed on

The temperature of the specimen can affect the results of an Izod impact test. As the temperature decreases, the material becomes more brittle and the impact strength decreases. This is because the lower temperature reduces the mobility of the polymer chains, making them less able to absorb energy.

Specimen Thickness

The thickness of the specimen can also affect the results of an Izod impact test. As the specimen thickness increases, the impact strength decreases. This is because the thicker specimen has more material to absorb the energy of the impact.

Notch Geometry

The geometry of the notch can also affect the results of an Izod impact test. A sharper notch will result in a lower impact strength than a duller notch. This is because the sharper notch concentrates the stress at the tip of the notch, making it more likely to fail.

Applications

Izod impact testing is widely used in various industries to assess the impact strength of materials.

It is particularly valuable in the following sectors:

- Automotive Industry:Evaluating the impact resistance of plastic components, such as bumpers and dashboards.

- Aerospace Industry:Assessing the impact strength of composite materials used in aircraft structures.

- Construction Industry:Determining the impact resistance of building materials, such as concrete and roofing tiles.

- Medical Industry:Testing the impact strength of medical devices, such as implants and surgical instruments.

Impact Strength Data in Design and Material Selection

Impact strength data obtained from Izod impact testing plays a crucial role in the design and selection of materials.

Engineers and designers use this data to:

- Predict the performance of materials under impact loading:This helps them optimize designs to withstand potential impacts.

- Compare different materials:By comparing the impact strength of various materials, they can select the most suitable option for a specific application.

- Establish quality control standards:Impact strength data can be used to set acceptable limits for the impact resistance of materials.

Advantages and Limitations

The Izod impact test offers several advantages:

- Simple and standardized:The test procedure is well-established and standardized, ensuring consistent results.

- Relatively inexpensive:It is a cost-effective method compared to other impact testing techniques.

- Provides comparative data:The results can be easily compared to industry standards or data from other materials.

However, the Izod impact test also has some limitations:

- Not suitable for all materials:It is primarily designed for rigid materials and may not be suitable for flexible or brittle materials.

- Not representative of real-world loading:The impact load in the test is applied at a specific location and direction, which may not fully represent the actual loading conditions in an application.

- Susceptible to specimen preparation:The shape and dimensions of the specimen can influence the test results.

Questions and Answers

What is the purpose of an Izod impact test?

An Izod impact test determines the energy absorbed by a material when subjected to a sudden impact force, providing insights into its toughness and resistance to fracture.

How is the impact energy calculated?

The impact energy is calculated by measuring the height difference between the initial and final positions of the pendulum after it strikes the test specimen.

What factors can affect the results of an Izod impact test?

Temperature, specimen thickness, and notch geometry are among the factors that can influence the results of an Izod impact test, highlighting the importance of controlling these variables for accurate testing.